The Roadster’s 2.x series Power Electronics Module (PEM) is a complex 3-phase inverter assembly, essentially the heart of the drivetrain, and is no longer in production. Our warranted refurbish/rebuild services restore reliability by replacing predictable wear items and implementing field-proven Engineering Change Orders (ECOs) that have emerged as these cars have aged. Unlike its predecessor, the 1.5 series PEM, the differences between the two are minor, and both are equally sensitive to aging electronics and components, making a rebuild and upgrade vital since production halted over a decade ago.

A proper rebuild requires specialized production and test equipment:

hi-pot testers, surface-mount soldering and vacuum reflow tools, calibrated torque assembly, machine-shop fixtures, and firmware tooling. A full 2.x PEM rebuild typically replaces 48+ wear components (more if IGBT transistors test marginal).

Service is performed in-house by Roadster EE engineers in an electronics lab. Each PEM is disassembled, cleaned, reworked, components replaced, re-sealed, and validated under load. Turnaround and final scope depend on the condition and the parts’ state. Shipping/handling is available for out-of-US clients.

| Level | Scope & Key Inclusions |

| 2.x PEM – Full Rebuild Price: $6504.87 |

All wear components are replaced, and engineering change orders (ECO) are resolved and updated. |

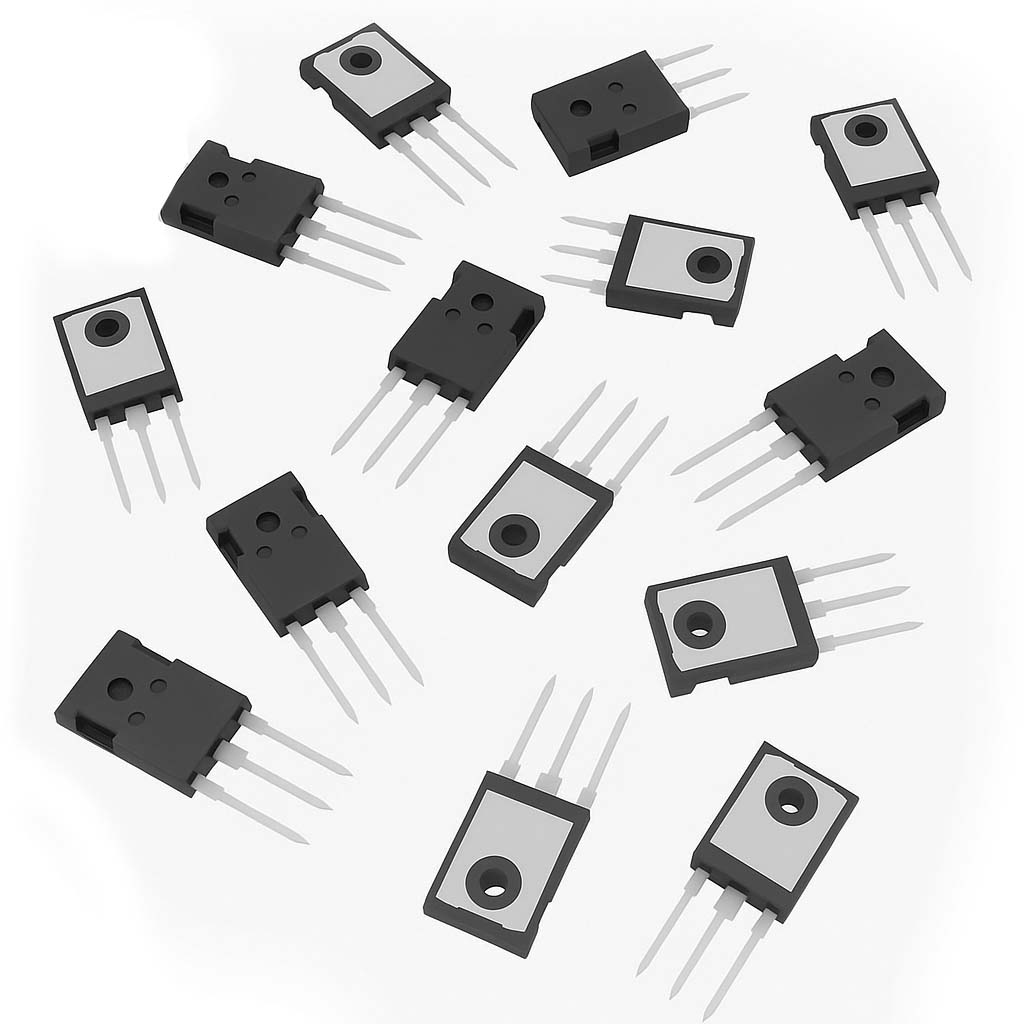

Original IGBT thermal/insulating dielectric pads are an inferior-sourced product that dry and crumble with age, reducing the gap between IGBT power transistors and aluminum heat sinks and risking shorts to ground. (One of many GMC-issued ECOs.)

With ~400 VDC and hundreds of amps present, a shorted IGBT transistor is usually a thermal event, sometimes damaging upstream logic boards (none are in production).

We remove, prep, and install modern high-reliability pads to restore thermal and dielectric performance.

The sole 12 V driver-board fan ages like a PC fan; bearings wear and airflow drops. We replace it to restore proper cooling across the logic/driver boards.

There is only one fan inside the PEM. Unlike the larger external PEM heat-sink cooling fan (which keeps the PEM and drive motor cool),

This small internal fan cools the inverter driver boards, a vital process.

Annual service cycles can push 90° pins backward, reducing current capacity and burning the socket. We replace/rework the connector and modify the housing to eliminate pin regression.

The connector is marginally sized for worst-case current. During yearly PEM cleaning, plug/unplug cycles can deflect pins into the socket housing.

reducing amperage handling until the socket burns. Our rework prevents future regression during maintenance.

Undersized SMD chains overheat and discolor boards. We install correct resistance/wattage parts and remediate the PCB as required. (One of many GMC-issued ECOs.)

These series-connected surface-mount resistors are part of the battery management system. The uprated network restores proper dissipation and reliability.

We back up the Roadster’s identity and battery metrics before service to protect against file-system corruption and enable swift recovery.

The VMS stores vehicle identity and battery metrics. We capture a verified backup for every Roadster that enters our service center, so recovery is possible after unexpected corruption or chip failure.

Electrolytic capacitors are used as filters in the DC-to-AC inverter. With a 7–8 year shelf life, they dry out and their ESR rises, increasing stress on IGBTs and overall PEM workload.

If not replaced proactively, heat rises, and severe cases can precipitate IGBT failure. In critical-power and solar systems, timed capacitor replacements are standard practice; we apply the same discipline here.

There are 84 IGBTs across three-phase boards that convert DC to three-phase AC for the induction motor.

We electrically evaluate the full population and replace any marginal or failed devices.

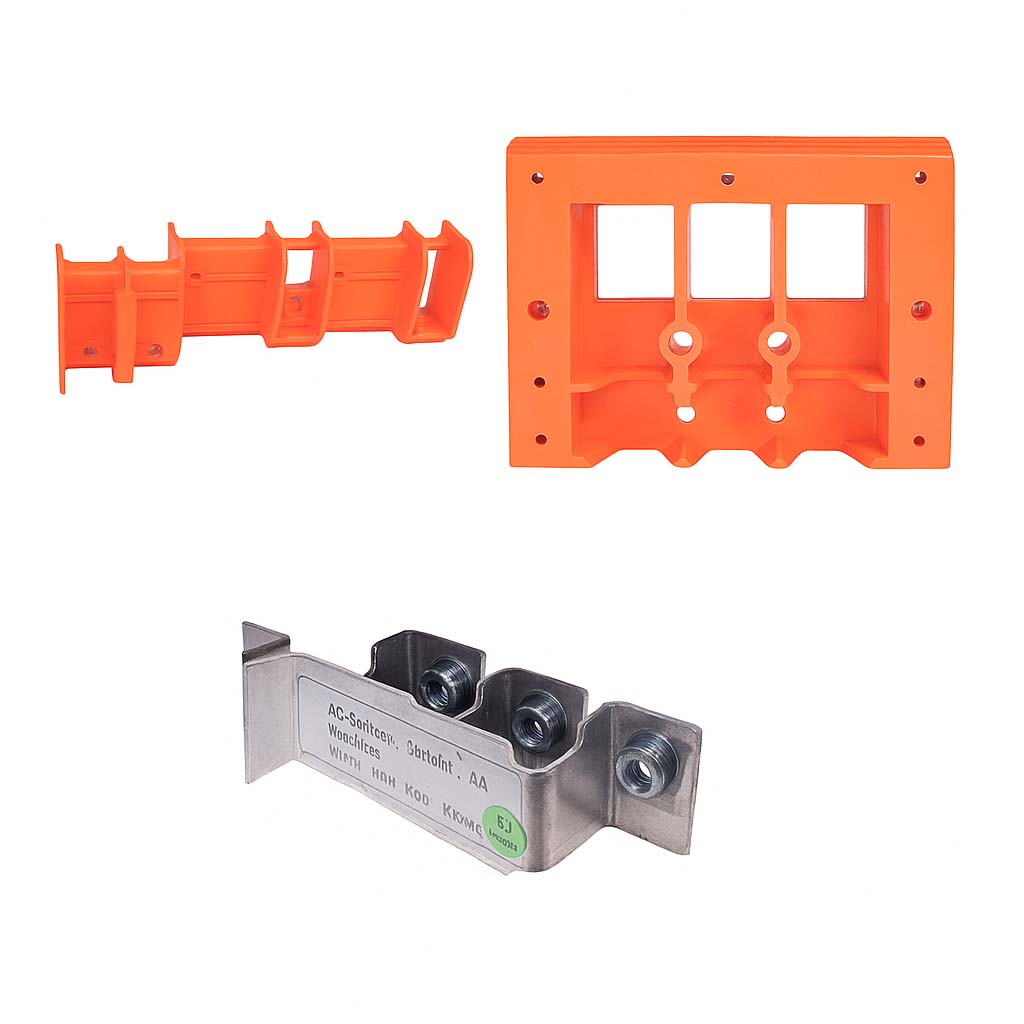

After a decade of heat and torque cycling, the OEM injection-molded ABS blocks become brittle. Annual PEM removal for preventive cleaning means repeated cable removal and re-torquing, which accelerates cracking, creep, and stripped threads. Many blocks are found cracked, crumbling, or hollowed out during rebuild. We replace worn blocks with improved 3D-printed versions and re-engineer the load connections. The copper bus bars are refitted with M8 PEM nuts so clamp torque is moved to the copper bus bars rather than the plastic housing’s captive nuts, and brass threaded inserts are inserted into the blocks (not self-tapping screws) for durable, repeatable service cycles without thread pull-out.

Contactors are a mechanical device that allows a small signal from the circuit boards to direct high current and voltage signals. As the contacts repeatedly switch from open to close, routing charge and motor control signals, arcing occurs and, over time, the metal contacts deteriorate, eroding and pitting.

We replace all Mega-Pole relays and contactors.

Relays are mechanical devices that allow a small control signal from the logic printed circuit boards to switch high current and voltage signals.

These mechanical devices have metal contact pads that corrode and erode over time, compromising signal flow. All are replaced for increased reliability.

There are a number of fuses in the Tesla Roadster PEM. These devices protect sensitive circuitry from overload. There are both low- and high-current fuses in the PEM; both are tasked with breaking a circuit in the event of excessive current.

Because fuses are binary devices (open/closed), we replace them proactively, since the Power Electronics Module is the heart of a Roadster.

For owners outside of the USA, ship your PEM to:

Gruber Motor Company

203 W. Lone Cactus Dr.

Phoenix, AZ 85027

USA

Maintenance Tip:

Yearly annual maintenance is highly recommended to clear the power-transistor heat sinks that get clogged by low-mounted, unfiltered cooling fans.