A Tesla Roadster Power Electronics Module (PEM), is a complex 3 phase inverter assembly, full of electronic components, and essentially the heart of the vehicle drive train.

This fully warranted PEM rebuild service includes replacing all known and predictable component wear items outlined below, a process much like a full engine overhaul in an internal combustion engine, to rejuvenate the lifespan of this critical Roadster sub-assembly.

This level of service is a complete rebuild, of an assembly no longer in production, resolving all engineering change orders (ECO’s) that have revealed themselves as these cars have aged.

A range of special test and production equipment is required to properly perform a full PEM rebuild, including hi-pot testers, surface mount soldering equipment, vacuum solder tools, specific torque setting, machine shop tools, and firmware tools and expertise. 48 components are replaced during our full PEM rebuild, or more dependent on whether the input and output blocks are broken and any marginal IGBT transistors need to be replaced.

We have two levels of PEM Refurbish/Rebuild services available listed below.

This level of PEM repair/rebuild resolves all known engineering defects in the Power Electronics Module (PEM). It is a prerequisite minimum level PEM service designed to resolve deferred maintenance, which left unresolved, can cause damage to the PEM.

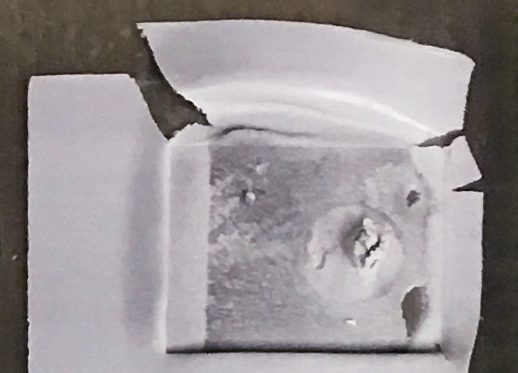

Transistor Insulating Material

We first discovered this age related engineering defect in 2014 while repairing a Roadster PEM. This insulating material not only provides a thermal conduit for the heat generated from these IGBT Power Drive Transistors, but insulates the high voltages and currents from the aluminum heat sinks. This original barrier material has been breaking down as it ages, drying and crumbling, and eventually shorting the transistors to the heat sinks disabling the car.

Internal PEM Cooling Fan

This 12 Volt fan is no different than the CPU cooling fan in your PC. You are probably aware how often these fail as they age. Fans are rotating mechanical devices with bearings that eventually wear out, just like your PC fans that do not last forever. There is only one fan inside the PEM. Unlike the larger external PEM heat sink cooling fan, which keeps the PEM and drive motor cool, this small internal fan cools the inverter driver boards, a vital cooling process.

PEM Cooling Fan Connector

The PEM cooling fan connector is marginally sized for the worst case current required. The major failure occurs from predictable and recommended yearly PEM cleaning when the connectors are plugged and unplugged. The 90 degree connector pins deflect and regress into the PEM socket housing, reducing the amperage handling capacity, which eventually burns up the socket. We replace and rework this connector and modify the pin housing so no pin regression is possible during annual PEM maintenance.

Bleed Resistors

There are a series of bleed resistors on a circuit board inside the PEM, part of the battery management system. These series connected surface mount resistors were originally undersized, overheat, and sometimes burn up. Visible signs of Printed Circuit Board discoloration is visible on all PEMs. These surface mount resistors are upgraded and replaced with the correct resistance and wattage values.

GPS Firmware Corruption

Since the summer of 2019, the Garmin GPS firmware has had a week number overflow bug that causes the GPS to roll back to the year 2000. Although this does not affect overall functionality, it does cause the timestamps in the log files and battery health logs to be recorded incorrectly leading to to problems diagnosing faults. We reprogram the Roadster firmware to resolve this issue

Complete VMS Firmware Backup

The Tesla Roadster identity and battery metrics are stored in the file system on the VMS (Vehicle Management System). During service, or failures and power losses in the Roadster, the file system can get corrupted and keep the VMS from booting properly. This unique data, on every Roadster that comes into our Service Center, is backed up and stored, for you, and available in the event of corruption or chip failure.

12 Volt Instrumentation Battery Upgrade

If the Roadster is at our Service Center for this PEM upgrade service, we include, at no charge, a 12 Volt auxiliary instrumentation battery. This battery upgrade converts your car from a 12 Volt 8 Amp Hour Motorcycle Battery, to a 12 Volt 12 Amp Hour Gruber Power Services (GPS) battery designed for electronics applications, and 4 more Amp Hours of energy.

This fully warranted and certified PEM rebuild service includes replacing all known and predictable component wear items outlined below, a process much like a full engine overhaul in an internal combustion engine, to rejuvenate the lifespan of this critical Roadster sub-assembly. This level of service is a complete rebuild, of an assembly no longer in production, resolving all engineering change orders (ECO’s) that have revealed themselves as these cars have aged.

Since we will be working on boards, and sub-assemblies, this option also includes repairing a failed PEM.

This level includes all these previously listed engineering changes

And - Replacement of all these wear items listed below:

Electrolytic Capacitor Replacement

Electrolytic Capacitors are used as filters in the DC to AC portion of the inverters. They have a shelf life or around 7-8 years. Electrolytic Capacitors dry up with age. Over time, they become resistive which places additional loads on the IGBT output transistors making the PEM work harder. If they are not periodically replaced, they eventually heat up, and in severe cases, can cause the output transistors to fail, or blow up inside the PEM.

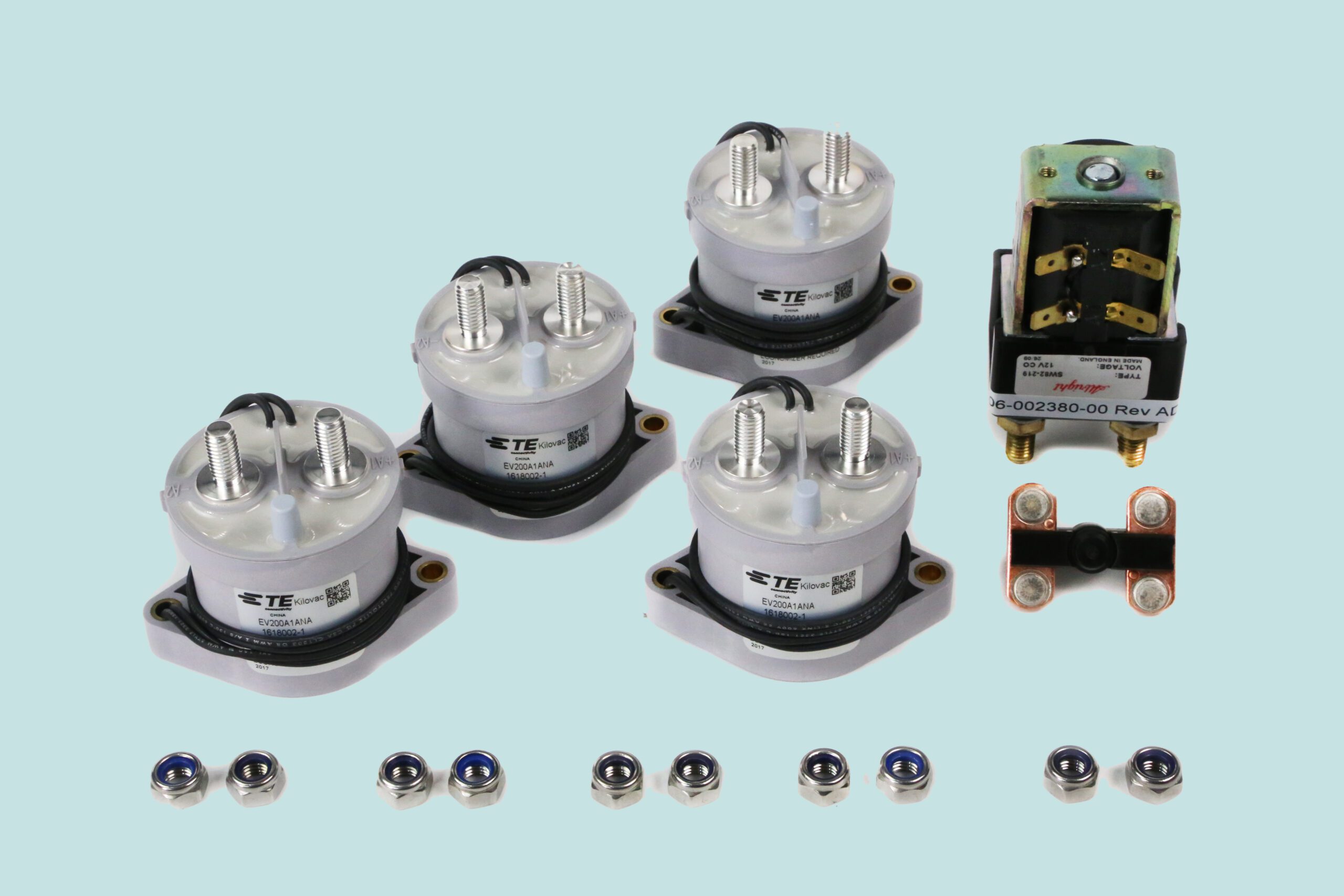

Contactors and Mega-Pole Relays

Contactors are a mechanical device the allows a small signal from the circuit boards to direct high current and voltage signals. As the contacts repeatedly switch from open to close, routing charge and motor control signals, arcing occurs, and over time, the metal contacts deteriorate, eroding, and pitting.

We replace all Mega-Pole Relays and contactors.

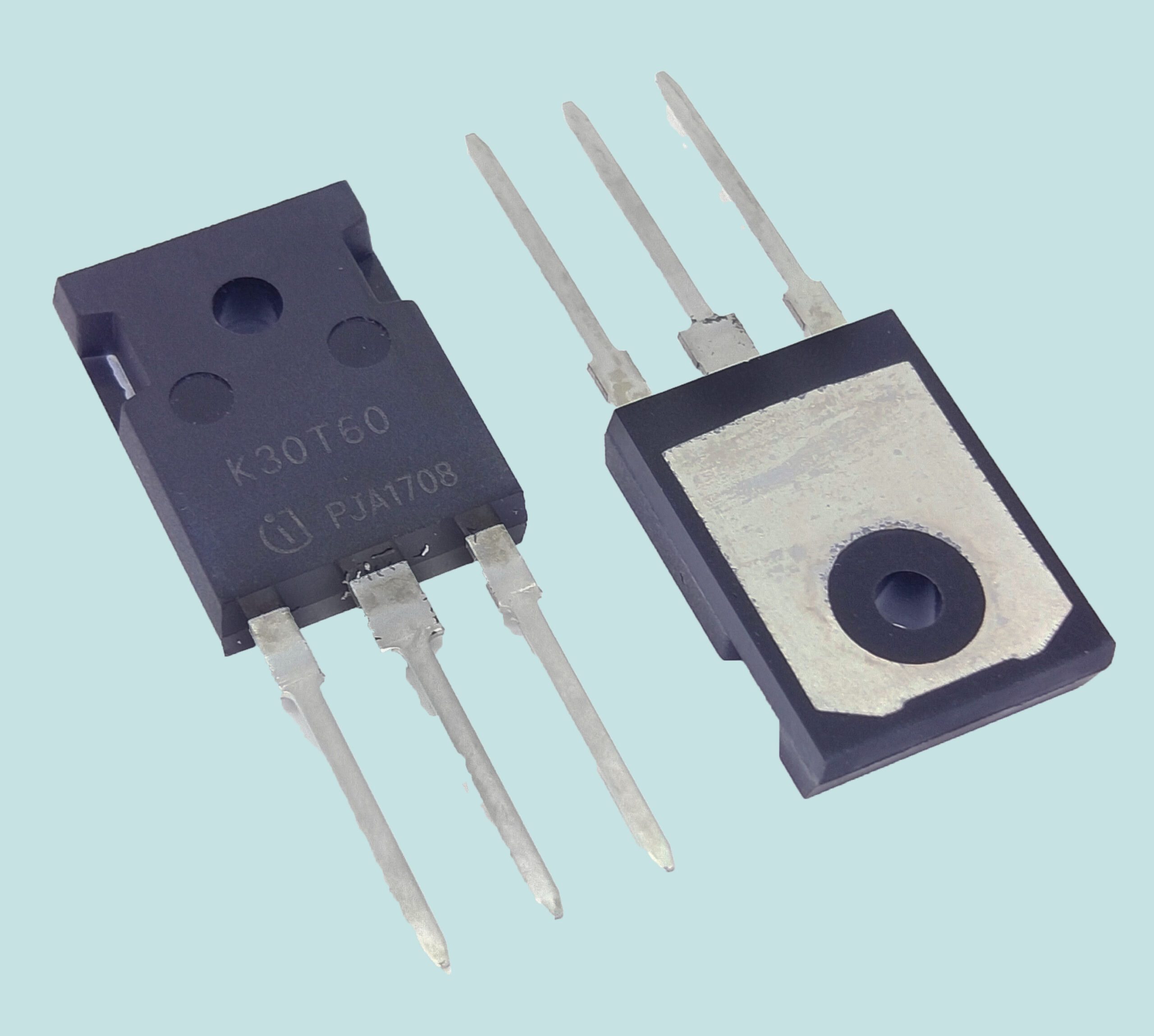

IGBT Power Transistors

There are 84 (IGBT) power transistors on 3 phase boards in a PEM. These are part of what converts the DC power to 3 phase AC, to drive the AC Induction Motor which propels the Roadster. We evaluate the condition of all power transistors, which are often compromised due to failing insulating material. With electronic test equipment, we isolate and replace any marginal or failed IGBT transistors.

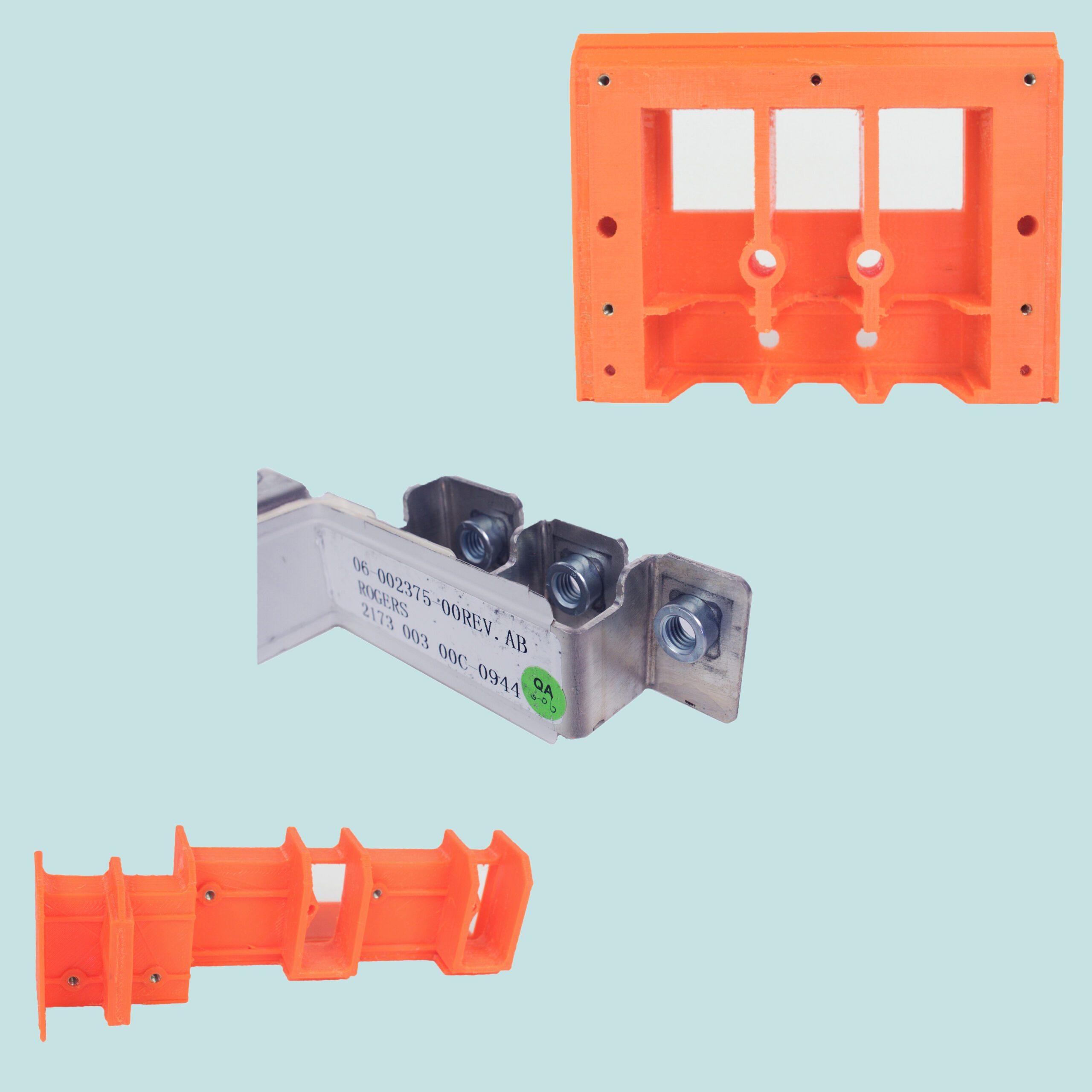

DC Input and Motor Output Insulating Block Upgrades

These injection molded ABS plastic connector blocks are over a decade old, and becoming increasingly more brittle with age. Repeated loosening and re-torquing of both input and output connections in the PEM, usually performed annually, weakens this connector block. Most are crumbling, cracked, and marginal.

These insulating blocks direct high amperage and high voltage signals. We modify and improve on the design by inserting pemnuts in the bus bar, and replace these old worn parts with new 3D printed, improved versions.

Relays and Interlock Switch

Relays are also mechanical devices that allows a small control signal from the logic printed circuit boards, to switch high current and voltage signals.

These mechanical devices have metal contact pads that corrode and erode over time compromising signal flow. All are replaced for increased reliability.

Fuses

There are a number of fuses in the Tesla Roadster PEM. These devices protect sensitive circuitry from overload. There are both low and high current fuses in the PEM. Both are tasked with breaking a circuit in the event of excessive current.

Fuses are simple devices, either open or closed. Since a Power Electronics Module is the heart of a Roadsters, and the devices are relatively inexpensive, all are replaced.