Aging and brittle PEM Motor Connector Block

Tools Required:

Wrench, Hammer, Flat-head Screwdriver, Phillips-head Screwdriver

Approximate time to complete:

14.75 hrs.

Aging and brittle PEM Motor Connector Block

Introduction

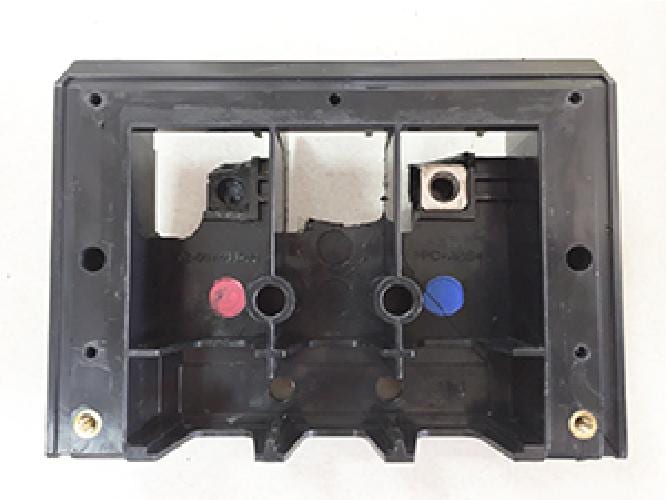

This injection molded ABS plastic connector block becomes increasingly more brittle with age. Repeated loosening and retorquing of the 8MM bolts connecting the 3Ø AC Induction Drive Motor to the PEM, usually performed annually, eventually weakens this connector block. This PEM output port is the high amperage, high voltage, connection to the drive motor.

Three square nuts loosely recessed into this connector block eventually place enough stress onto the connector block during loosening or tightening, cracking the ABS square nut captivator pocket, and in severe cases as shown, the block crumbles.

Images

- Existing PEM Motor Connector Block

- Crumbling PEM Motor Connector Block

- Broken Square Nut Captivator Housing

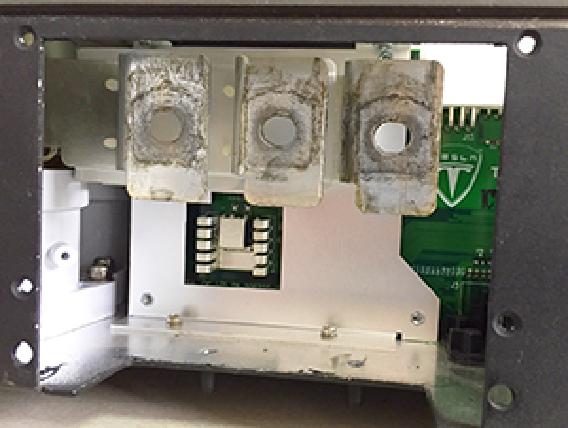

- NEW 3D Printed Block with cutouts

- 3Ø PEM Motor Driver Bus Bars

- PEM Nut to be pressed into Bus Bars

Corrective Action

The connector block was a proprietary Tesla Roadster only design, and the original mold has been scrapped. 3D printing allows for a reasonable replica, and a design improvement is embedding pemnuts into the PEM Bus Bars during PEM upgrades (Bus Bars are removed for this procedure anyway). The cable mounting strain is now transferred to the pemnut and bus bar instead of the plastic housing. The Motor connecting block is also replaced with a 3D print version which provides direct access and clearance to the bus bars for Motor cable connection. We believe this connector block should be replaced during any PEM upgrade, or as-needed upon failure.