ESS Battery Pack Bleed Test Failure

Tools Required:

Wrench, Hammer, Flat-head Screwdriver, Phillips-head Screwdriver

Approximate time to complete:

6.25 hrs.

ESS Battery Pack Bleed Test Failure

Introduction

When the ESS Battery Pack fails to charge, charges erratically, or exhibits range variations, often the early ESS pack sheet rivets are failing.

The Roadster software tools “bleed test” indicates out of tolerance voltage drop across bonding plate to BMB sense lead. User visible errors on the Roadster touch screen are “ID 7 Battery Service Required”, or Error “259 Charge Aborted-Battery, Problem Service Required”. In debug mode, errors are “ID 7 Battery Bleed Scan Failure”, and/or “283 BSM Isolation Fault, 286 BSM Isolation Fault While Contactors Closed, 287 BSM Isolation Fault Before Charge”.

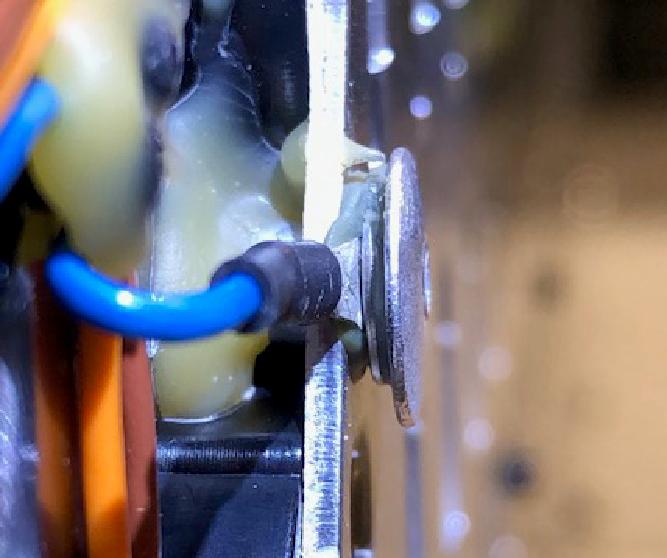

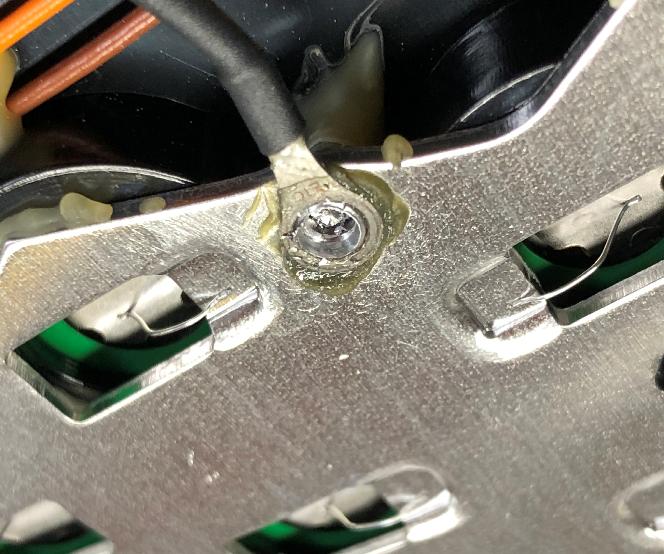

Earlier models of Roadster ESS packs used an aluminum pop rivet BMB sense lead mounting method on brick bonding plates. Once it was realized pop rivet clamping force was unpredictable and some were working loose over time, this process was replaced with an ultrasonic weld. Often sheets have been “re-manufactured, and the old rivets left in place on the brick bonding plates. Secondarily, we find 3414 Loctite oozing into certain rivets affecting the quality of connection. Some rivets on affected sheets also have liberal application of an anti-oxidant (Penetrol).

The washers on failing rivets are usually sticky and coated with this solution. Used in combination with Pop Rivets we feel this compromises the quality of connection over time, despite being a very low current connection to a BMB sensing circuit.

Images

- 3414 Loctite oozing into rivets

- Penetrol residue

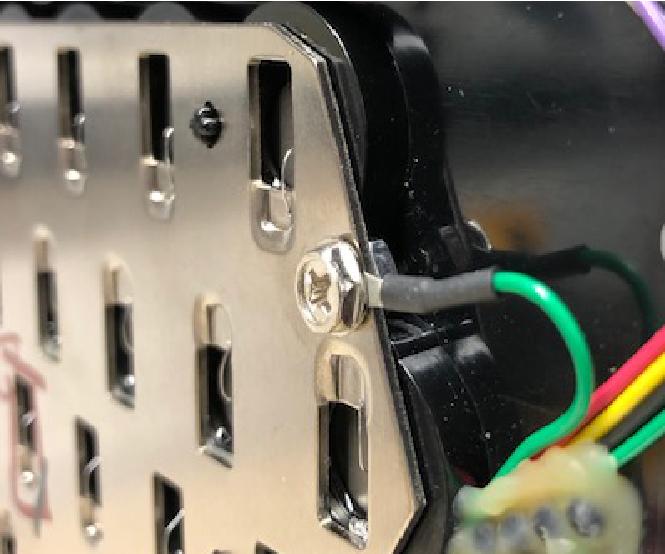

- 6-32 x ¼” PC grade hex head bolts

Corrective Action

A battery pull, and subsequent sheet removal is necessary. We recommend all rivets are replaced, on all bricks, in all sheets.

Once brick bond plates are exposed, pop rivets securing BMB board sense wires can be drilled out with a 1/8” drill bit. Bottom portion of Pop Rivet can be extracted with tweezers, and care should be taken not to allow metal drill fragments to migrate into brick connecting points.

The affected Pop Rivets are removed. Each sensing wire eyelet and bond plate entry point is cleaned and rivets are replaced with 6-32 x ¼” PC grade hex head bolts with anti-slip teeth, torqueing them to 20 inch pounds, and finishing the conversion with an application of Loctite.

Bleed tests are run before and after sheet rivet removal and replacement to confirm operation.