The Tesla Model S propulsion battery pack is one of this centuries most innovative breakthroughs.

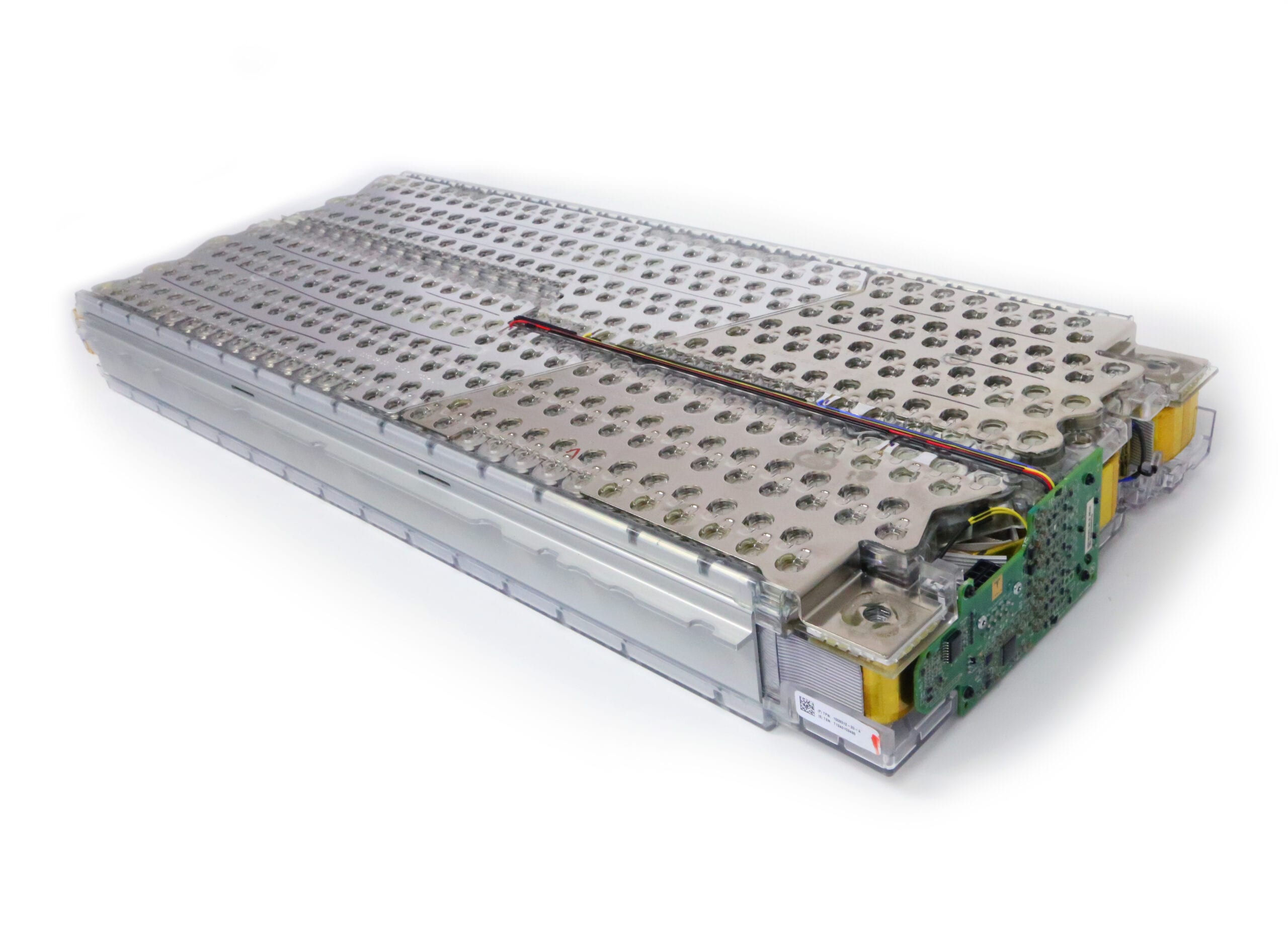

A collection of thousands of small form factor 18650 Lithium Ion cells, assembled into parallel connected bricks, inside modules, is what propels a Tesla Model S for often hundreds of miles.

As batteries age, they naturally lose capacity. This, in turn, gradually shortens driving range. LI-Ion batteries age with use, or age with time, even if not used. The number of charge cycles also affect battery life.

Out of thousands of cells, occasionally one declines in performance, going resistive as it fails, and becoming parasitic. Since the battery architecture is a combination of parallel and series connections, any cells in a "brick" of parallel connected cells, is affected by the one parasitic cell, pulling down the voltage.

The Tesla drive train warranty, which includes the battery system, is warranted for 8 years, and battery pack replacement is free during the warranty period. Tesla does not repair main battery packs in the field or Service Centers. For out of warranty vehicles, a battery replacement is their only option, around $20K.

At GMC, we are able to go inside the battery pack, repair what is wrong right down to component, or cell level. If the failure is cell related, we isolate the declining cell(s), neutralize them, and restore full functionality for a fraction of replacing the entire main battery pack.

If the failure is related to failing electronics, like the battery management board (BMB), we repair right down to component level restoring full functionality.

Battery Pack Pull and Enclosure Disassembly - $3600

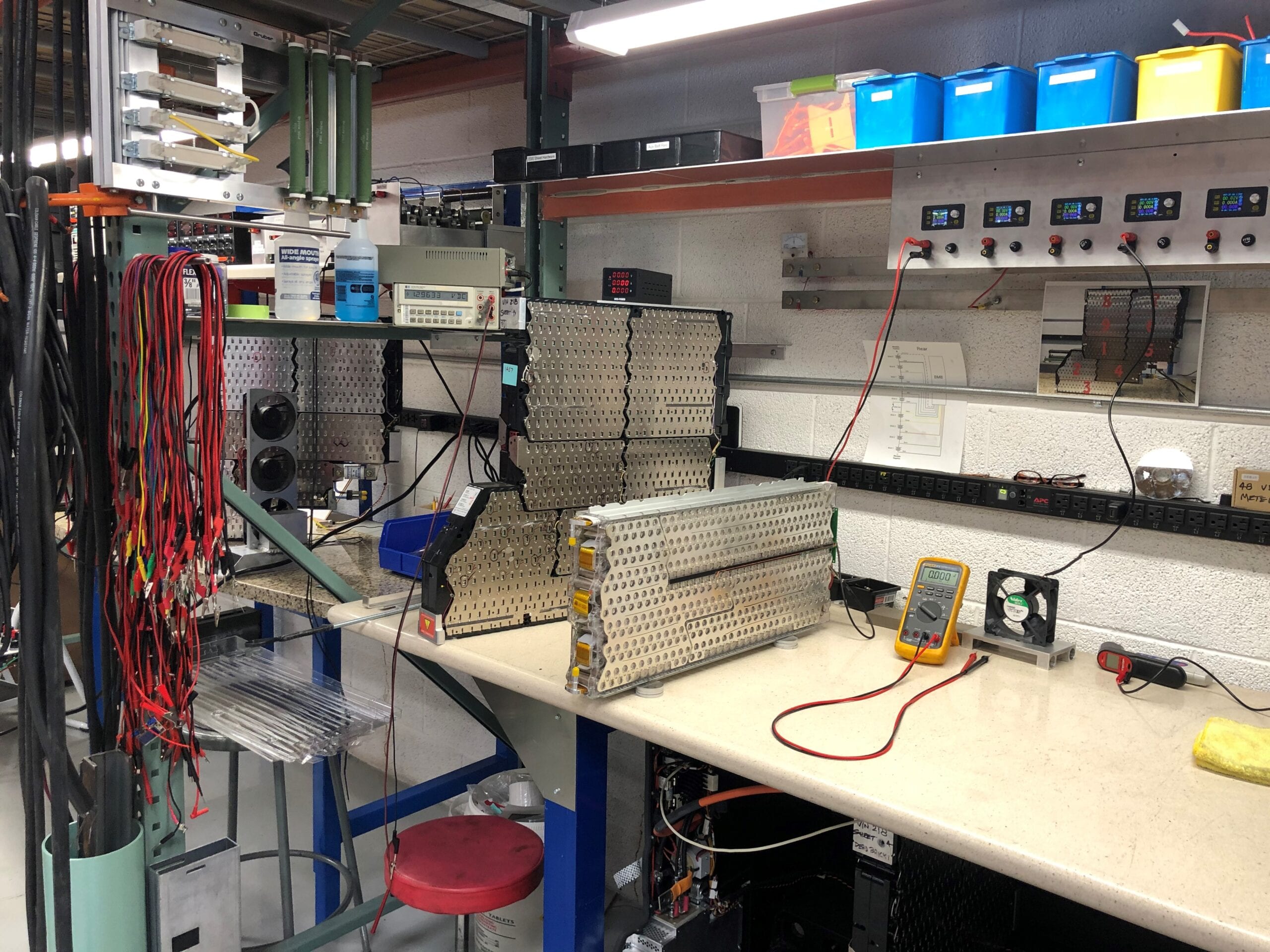

To remove a 1200 lb battery pack from a Tesla Model S requires a car lift with specialized hydraulic equipment, and a movable battery table capable of handling this weight.

The pack is cleaned, the top intumescent fire suppression blanket is removed, and a large top sheet metal lid cover is then carefully peeled off to expose clusters of LI-Ion modules containing cells, 7,104 in an 85KW pack.

Since the top lid is re-used, we clean off all remaining sealant caulk prepping it for re-installation.

We carefully inspect the battery pack tub for any signs of water ingress, coolant leakage, condition of CANBUS and High Voltage connectors, before removing the any battery modules for either failing cells, or Battery Management System board failures.

Cell Isolation and Neutralizing - $895 / Module

A declining range Model S usually has only one cell, in one module failing.

Diagnostic software identifies which of the 16 modules has a declining cell, in a brick. This module is then extracted from the pack, and moved to our cell isolation lab.

Using very sensitive measuring equipment, the declining cell is isolated, often only one out of 7104, and the dying cell is then neutralized.

This is followed by a combination of charging/discharging and load testing to verify a successful module/brick repair.

BMS Board Repairs - $795

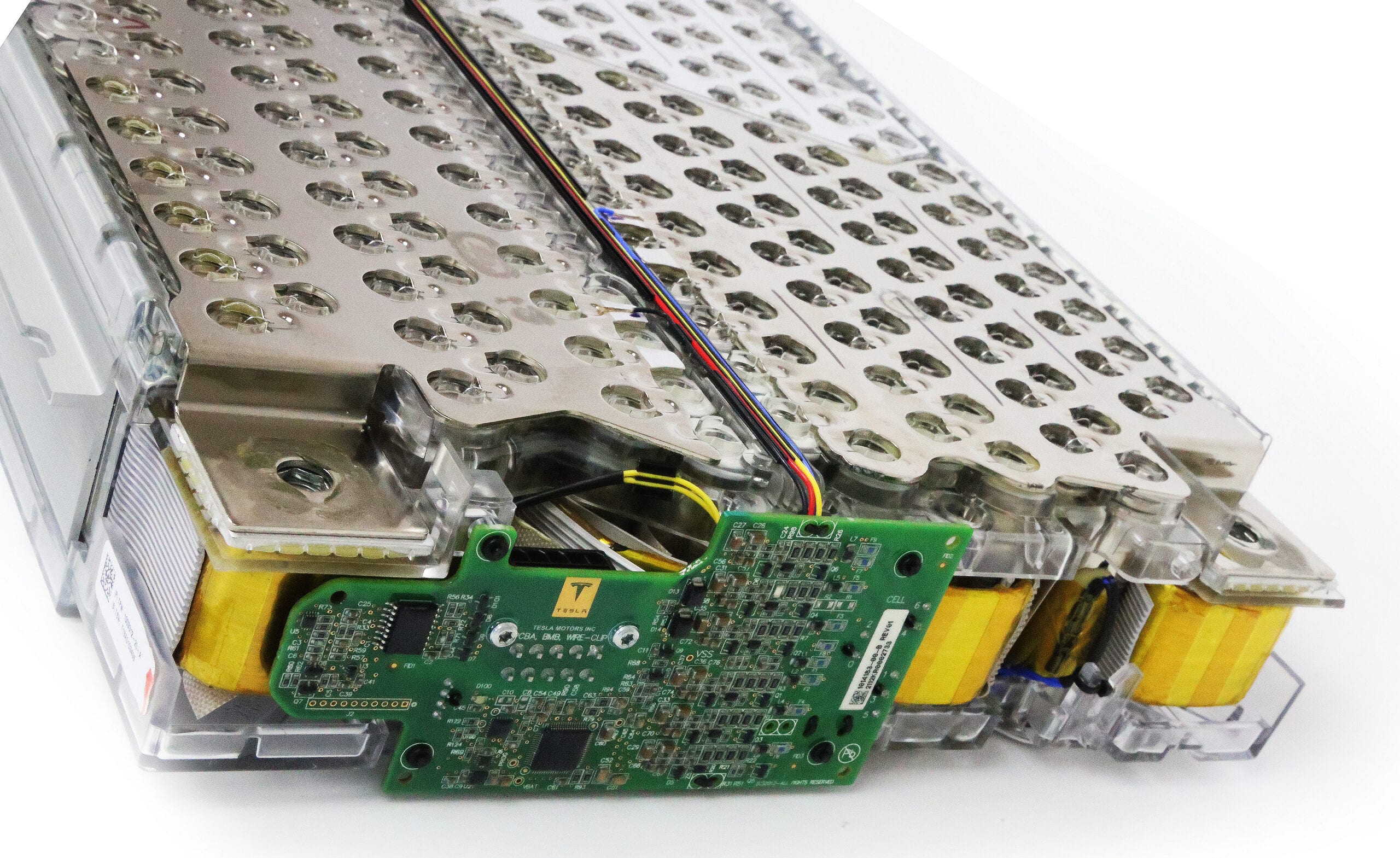

Each module also contains electronics as part of the Battery Management System (BMS) which controls and monitors charge rates, bleed rates for cell balancing, all part of the intelligent management of sophisticated battery management.

At times, component failures in the electronics also causes pack failure. Gruber Motor Company routinely repairs complex electronics down to component level, and resolves problems stemming from this section of the battery pack.

Module Replacement - $1895 / Module

Although rare, if enough cells have been compromised in a battery module, or water ingress occurred such as in flood damaged cars, a repair may not be as cost effective as the next option - replacement of the module from donor packs.

We carefully match the CAC value, age, and vintage of each module to make sure compatibility is maximized.

Each module contains 6 Bricks which consists of 74 individual 18650 cells connected in parallel in each Module. There are 16 of these Modules in each 85KW battery pack for a total of 7104 cells.

Gruber Motor Company (GMC) is part of Central Dispatch, a service that manages hundreds of automotive transporters all over north America. The members are all licensed, insured, and bonded transporters, skilled in auto transport.

Both specialized enclosed transport, and more common open transport are available. We provide bids for the vehicle owner to review, and handle payment, coordination, scheduling, for a seamless customer experience.

Upon vehicle receipt, we thoroughly clean it before it enters our state-of-the art Service Center.