How well are Roadster Battery Packs aging? August 15, 2020

Roadster Propulsion Batteries are Aging

These original Lithium Ion Roadster ESS (Energy Storage System) Battery Packs are now 10-12 years old. The battery came with a 245-mile range, and service life expectancy was initially projected at 10 years. Remarkably, and unexpectedly, they seem to be lasting beyond original life expectation.

A non-profit EV advocacy group, Plug In America concluded that Roadster batteries should retain between 80 to 85 percent of their original capacity after 100,000 miles. The majority of Roadster owners continue to drive and enjoy their cars, while a few are now beginning to see either a very gradual acceleration in range decline, and in far more rare cases, a rapid mileage range decline indicating a cell failure.

After 300 to 500 cycles at 100 percent depth of discharge, a lithium-ion cell’s capacity will drop to 70 percent. But partial discharge “reduces stress and prolongs battery life”, which is where most Roadster owners charge their batteries. Drain the batteries consistently to only 50 percent, as is often the case with electric cars that get plugged in frequently, and life expectancy of a healthy battery zooms up to 1,200 to 1,500 cycles. That, of course, translates to 366,000 miles, but don’t expect numbers like that on your odometer. Other wild cards such as frequency of fast recharge, storage temperature, can also affect battery life.

We are going to confine this discussion to Roadster ideal range measurements since this is the most common charge choice and indicator on the VDS screen.

Gradual Range Decline

Low use/mileage Roadsters, with charge cycles maintained in the “Standard Charge”, are seeing some age related range decrease. Plug In America, found that the Roadster’s battery backs are losing on average 3.7 “ideal miles of range” (Tesla’s proprietary battery-capacity measurement unit) every 10,000 miles. Most are still averaging around 150-170 ideal range distance at the end of a charge, even after 10 years.

Even high mileage Roadsters, accruing usage miles as daily drivers, although seeing a more aggressive long term ideal range decline, seem to be experiencing a linear decline, rather than an accelerated, exponential degradation in range. A few of our higher mileage Roadsters customers, are down to around 100 miles after an ideal charge.

Rapid Range Decline

… a new trend is surfacing …

There is a new trend surfacing as ESS packs age. Unlike the gradual range decline category, a new accelerated range decline, which is exponential, is beginning to crop up on Roadsters. This condition indicates one or more of the 6831 LI cells moving into resistive state, draining the rest of the parallel connected cells in a brick, comprised of 69 cells. The result is a far more rapid range loss, often up to 10 miles after each charge cycle. Roadster in this state need immediate attention, and if left unchecked, can move a Roadster into a “bricked” condition.

It takes only one of 6831 cells dying, to cause this condition.

The decline from a dying cell is sometimes so rapid, we have had functioning vehicles arrive bricked during transport to our Service Center. These vehicles are put on life support immediately upon arrival, infused with a controlled charge into the offending brick, so the rest of the cells do not suffer damage from low voltage states before a battery pull and surgery. (LI cells begin to self destruct if allowed to drop below 2 VDC) Protecting the 68 other cells in a brick with a dying cell from damage is essential, or the entire sheet becomes unusable and un-repairable.

After the battery is dropped, surgery consists of removing the affected sheet, and through a series of brick charge/discharge, and trend analysis, isolating and eventually neutralizing the resistive cell causing all the problems. When caught early, it is often only one cell in the pack.

To confirm this is what is going on, a free log file analysis, detailed in this newsletter – How to pull a Roadster log file, will identify which sheet/brick is responsible. We have a highly evolved parsing program that scrubs the continuously recorded Roadster log files, and converts them into plain english.

The log file analysis identifies the sheet, and brick, but cannot identify which cell in a parallel connected brick is dying. To isolate the failing cell in a brick requires access to the sheet, in the lab, and a different process entirely.

Does “Bricking” a battery affect the life of a pack?

Tesla Roadsters battery packs, if left uncharged, will sometimes reach a condition where the Roadster charge port no longer allows a charge. Rapid response to stabilize the car prevents long term damage, or a condition known as “hard bricked” where the only cost effective solution is a replacement donor pack. All this is preventable with rapid response outlined in one of our earlier newsletters – What to do if your Roadster gets bricked.

The good news is that bricked Roadster ESS Battery Packs, quickly stabilized and properly processed, do not seem to suffer any permanent damage or accelerated decline. If this “bricked” condition is caught early, within the first few weeks being ideal, and even up to 3-6 months, recovery through special equipment and processes in our lab results in a 100% successful fix, and a Roadster back on the road. Generally, no long term damage or further accelerated cell decline occurs if response is immediate. Successful recovery case histories we have accumulated support that properly processed bricked Roadsters suffer no long term damage or accelerated decline.

Unlike later Tesla vehicles, the Roadster, if left uncharged, is the only Tesla vehicle that reaches a dangerous low charge state where it will no longer accept a charge from the main charge port.

What is a “Remanufactured” Roadster battery pack

As Roadsters were first released, data collected from the field indicated some ESS battery packs would charge erratically, or exhibit range variations. Vehicle Display Screen (VDS) errors varied and the most common was “BSM Isolation Fault”. The Roadster software tools “bleed test” indicated an out of tolerance voltage drop across bonding plate to BMB sense lead, despite being a very low current connection.

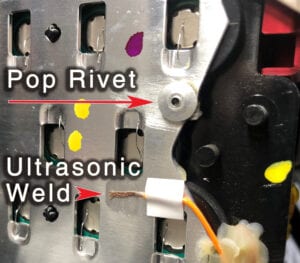

It was determined that earlier models of Roadster ESS packs used an aluminum pop rivet BMB sense lead mounting method on brick bonding plates in the sheets. In addition, and 3414 Loctite oozing into certain rivets, also affected the quality of connection.

Once it was realized pop rivet clamping force was unpredictable and some were working loose over time, this process was replaced with an ultrasonic weld connection.

As these Roadster Battery packs, exhibiting symptoms were recalled and reworked, the sheets and packs were then relabeled as “Remanufactured”.

Roadster ESS Pack Construction

Future Roadster battery pack considerations?

The Roadster ESS contains multiple overlapping safety systems – some active and some passive. Each sheet, or module, has its own microprocessor circuitry that monitors a wide range of conditions as well as actively balancing the cell voltage to help mitigate the danger of overcharging (and potential damage from over-discharge). There are sensors inside the ESS that sniff for smoke, check for the existence of water immersions (if the car were driven into a lake, for example), and continually monitor the pack to ensure that it is thermally stable. Each cell is independently fused, not once, but twice.

This early Tesla innovation, using what they initially called “laptop” batteries to propel the Roadster, became the foundation of EV battery systems, proving long distance travel was possible with a close to zero maintenance DC storage system.

The long awaited Roadster Battery replacement is not quite available yet. As of publication, Tesla seems to continue to signal a Roadster replacement battery pack solution is imminent. Speculation now is that it will be made with cells more closely resembling original 18650 performance, therefore minimizing changes to firmware and existing Roadster electronics, the majority of which has been out of production for a decade.

Although the original ESS Battery Packs are performing beyond expectations, they will eventually reach end of life, decline, and become unusable, and continued repair and recovery like we perform now will no longer be economically feasible as more rapid cell decline occurs as cells begin failing due to age. A Tesla replacement solution is essential to keeping this original fleet of cars alive.

Do not use impact wrenches on Roadster keyed lock nuts

The amount of force they apply to loosen or tighten these lug nuts is extensive. It is sufficient to cause locking wheel nut keys/fasteners and tools to break.

Actually, the impact wrench does not provide constant torque. Instead, it is more akin to putting a wrench on the nut or bolt that needs to be loosened and hitting it with a hammer, turning it in small, incremental stages. As power is applied to the impact wrench, an internal "hammer" strikes against an anvil, which is connected to the square drive on the end of the wrench. This attempts to force the tool (usually a socket) that is attached to the air drive to turn.

The sheer power of the impact wrench can damage the locking wheel nut key, and can also damage the locking wheel nuts. Instead, the locking wheel nuts need to be tightened by hand, using a calibrated ‘Torque Wrench’.

Finally, at publication, we are unaware of any Tesla Roadster wheels ever stolen. There is no standard lug nut key for the Roadster. There are actually dozens of variations, mostly hard to find and replace, and often sourced in the UK. We routinely replace them with matching standard original non-keyed TORX lug nuts to eliminate the hassle and risk of breaking.