Tesla Roadster

Headlight Restore & Rebuild

Roadster headlights take a beating, front and center placement on the car, and as they age, a number of flaws begin occurring. Back in the day, you could drive down to the nearest Tesla Service Center, and buy replacements. This days are over since these assemblies are out of production.

Unless the Roadster has been pampered, driven little, stored indoor in temperature controlled environment, and under cover, here are common failures:

- The clear coating used will begin to flake like a bad sunburn

- Lenses fog up inside from moisture ingress

- The parking light lens will fall off inside and roll around inside the assembly

- Weather seal around the assembly will crumble and deteriorate

The bottom line is headlight deterioration can become a blight on an otherwise beautiful car. All of these problems can be fixed and improved upon to prevent future issues. These headlight assemblies have been out of production for years, but a completely rebuildable, upgradeable, and repairable. Depending which option is selected, our rebuild process includes:

- Removing old clear coat and applying a Euro spec UV resistant two part product

- Ceramic coating the finished lenses

- Removing the hot incandescent parking light bulb, repairing the lens, and upgrading to cool LED

- Deoxidizing and clear coating the interior lens surfaces

- Replacing the brittle rubber caps which allow moisture ingress, and sealing them with stainless steel clamps

- Sealing all ports with silicone to stop moisture

- Applying new foam weather strip

- Replacing all aged, old tech incandescent bulbs with LEDs

Stage 1

Basic Headlight Rebuild – $615 / Pair

This basic level of Headlight repair/rebuild resolves the most common issues including resolving original design issues like using a hot incandescent bulb in the parking light socket which eventually melts the mounting tabs and loosening the lens and having it roll around inside the headlight.

Parking Light Bulb Upgrade

The Roadster originally came with incandescent bulbs in this socket.

Since this type of bulb has a hot filament, inside a tight enclosed space, with age, the mounting tabs on the lens cap inside the headlight discolored and melted from the heat, eventually causing the lens to break free and roll around inside the headlight. We replace the old incandescent bulb with a new much cooler operating temperature LED.

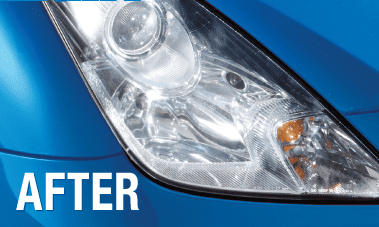

De-Oxidize and Clearcoat Lens

As Roadsters ages, and are exposed to UV from the sun, the original clearcoat applied to the headlight lenses begins to peel like a bad sunburn.

We not only de-oxidize and polish the lens, but apply a Euro spec UV resistant coating which seals the plastic and offers long term protection. To finalize this layer of added protection, we then ceramic coat the lens.

New Foam Weather-stripping

This weather-stripping provides the carrier between fenders and headlights..

With age, this foam material compresses, hardens, and shrinks, often making gaps, peeling, and flaking.

Our rebuild process removes the old material when the lenses are removed, and a new 3M quality weather-stripping is applied to seal the headlight against the fenders.

New Rubber Caps and Seals

The primary cause of moisture and water ingress and fogging in the headlight housings is these rubber caps which are supposed to seal the bulb openings.

With age, they harden, expand, become brittle, and loose their ability to seal out dirt and moisture.

We replace these with new caps, and seal them with a stainless steel clamp.

Headlight Assembly is Sealed

The headlight lens is removed, cleaned and polished on the inside, and re-attached to the headlight tub with a urethane sealant.

All headlight tub openings, which allow water, dust, and moisture buildup with fogging inside the headlight assembly, most commonly manifested after a car wash, are sealed preventing any further intrusion of contaminants.

Ceramic Coating on Lens

After all the improvements are made to the headlight, the final layer of protection is a ceramic coating application.

This liquid polymer that chemically bonds with the vehicle’s paint protection film, creating an additional layer of protection.

Ceramic Coating will not wash away or break down and does not require repeated application every few months unlike traditional waxes.

Stage 2

Intermediate Headlight Rebuild – $720 / Pair

This level of Headlight repair/rebuild includes all improvements from Stage 1, and polishing the inside of the headlight lens.

Polish the Inside of the Lens

With age and moisture intrusion, often the inside of the lens becomes cloudy and discolored.

Resurfacing the outside of the lens may be insufficient for that “like new” or better clear appearance, and polishing the inside of the lens achieves that goal.

Stage 3

Full Headlight Restore & Rebuild – $1295 / Pair

This level of Headlight restore, rebuild, and repair, addresses all the previously mentioned improvements in level 1 and 2, but adds a 100% LED conversion replacing all the old incandescent bulbs. Carefully selected load resistors are included to satisfy the firmware which is looking for incandescent bulbs.

Replace Low and Hi Beam Bulbs with LEDs

Since the Roadster came out in 2008, lighting technology has improved exponentially with not only much brighter and cooler performance, and less drain on the battery system.

We recommend this final improvement to complete any restoration of the stock Roadster headlights.

Stage 4

Lens Replacement Adder – $985 / Pair

We are partnered with a major headlight manufacturer, and by providing them original Tesla Roadster Headlight specifications, have commissioned them to replicate the original lens molds, to recreate brand new headlight lenses, for a perfect result. This service is an adder to Stage 1-3.

Replace Headlight Lenses

A small percentage of Tesla Roadster Headlights have damaged lenses which do not allow a perfect restoration.

Common issues are cracked, badly chipped, or broken lenses from impact.

Another more common aging issue problem are spider cracked lenses, as shown, for which all the polishing and resurfacing in the world cannot restore the lens to perfect condition.

We not only replace the headlight lens under Stage 4, but provide the same extra level protection including UV resistant coating, and liquid polymer ceramic coating as outlined in Stage 1 to preserve your new lenses.