Tesla Roadster

Battery Electronics Rebuild

The Tesla Roadster Energy Storage System (ESS) propulsion battery pack contains two electronic sub-assemblies vital to operation.

Inside each pack is a DC-DC converter (APS) Assembly, and a Battery Safety Module (BSM), both of which have aging, large electrolytic capacitors now going on 10 years plus. The service life of these components is 7-8 years.

We have completely reverse engineered these two out of production assemblies, with a full set of schematics, test points and procedures, and BOM.

We recommend whenever a battery pull is performed on a Tesla Roadster, for brick/sheet repair, sheet replacement, APS Unit service, or a 3.0 battery upgrade. This is an opportune time to address these aging component replacements.

DC-DC Converter

APS DC-DC Converter Unit Rebuild

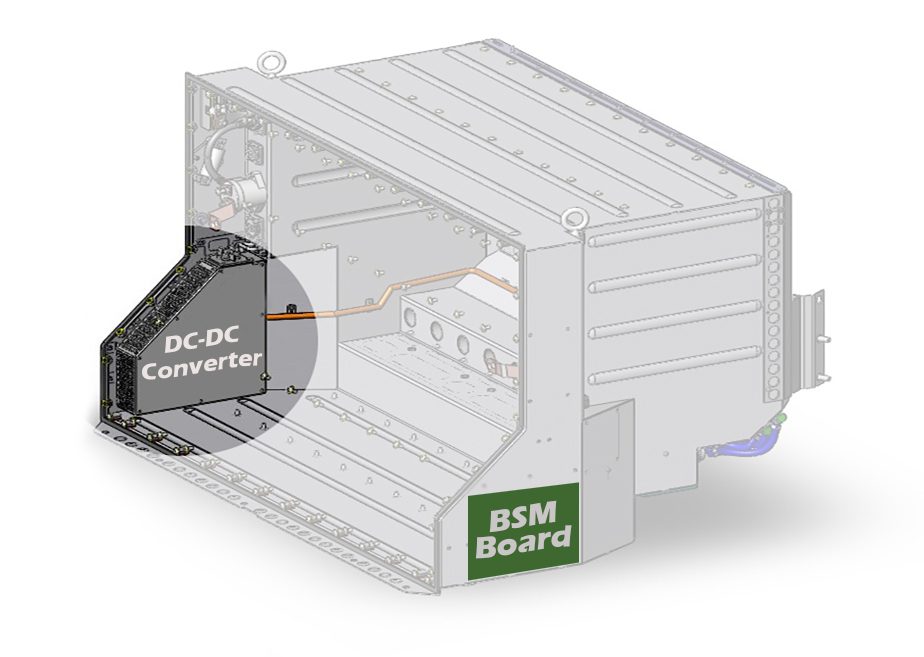

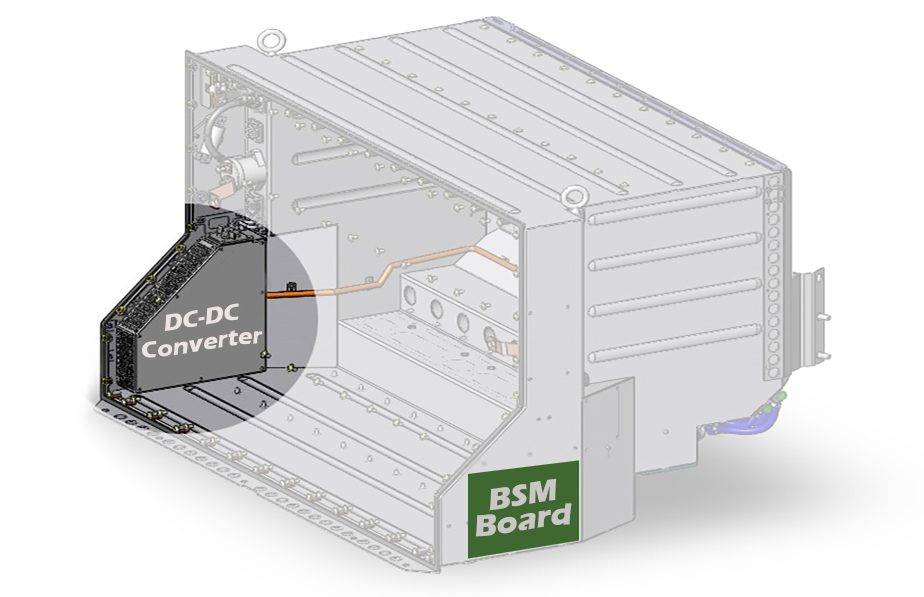

This assembly is buried deep inside the ESS Main Battery Pack.

It’s function is to take the 400 Volts DC from the propulsion battery and convert it to 12 VDC and 13.6 VDC for all the low voltage devices in the Roadster.

It is a highly customized assembly, no longer in production, and similar replacements are not available due to unusual geometry so it fits inside the main pack, and being and extension of the cooling system in the Roadster.

Two vendors originally custom made this assembly for Tesla – Martek (out of business), and Delta Electronics, the replacement vendor Tesla selected, will no longer manufacture this custom Roadster product. Even if they restarted a production line, the Minimum Order Quantity (MOQ) would be unrealistic.

Rebuilding this assembly appears to be the only cost effective option at this point.

Rebuild - $895

Inside the ESS Main Battery Pack is the Auxiliary Power System (APS) or DC-DC converter, along with the Battery Safety Module (BSM).

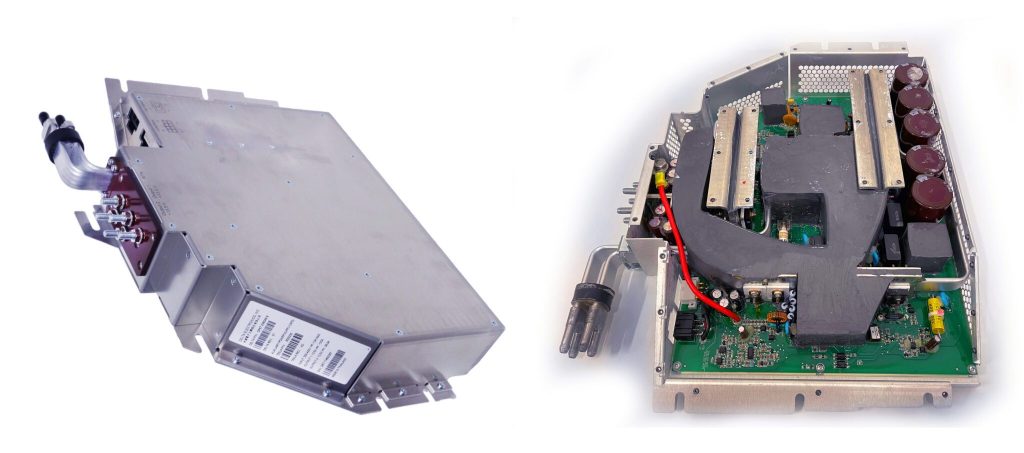

Martek Brand APS DC-DC Converter

The APS DC-DC Converter is full of Electrolytic Capacitors, last installed in 2007-2008. The dark areas are thermal potting compound assisting with heat transfer to the cooling jacket plumbing circulating through this assembly along with the battery sheet cooling system.

Defined in this image are the large electrolytic capacitors most prone to age related failures. These components are filters in both the 400 VDC high voltage section, and 12 VDC low voltage output section. In addition, relays, which are mechanical switching devices, are also replaced.

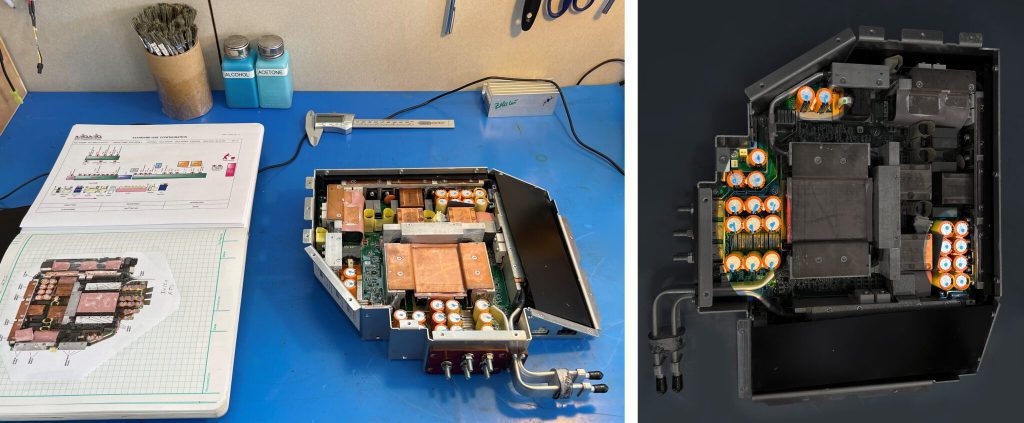

Delta Brand APS DC-DC Converter

This is the second generation custom APS unit Tesla used after realizing the Martek brand unit was not robust enough.

Highlighted in this image are the 22 electrolytic capacitors most prone to age related failures which are part of the rebuild procedure.

This is an example of failing capacitors in a Uninterruptible Power System (UPS) module. Visible are two types of failures from age, a bulging top indicating building pressure from overheating due to resistance building in the capacitor as they age, and one that has blown its top from excessive pressure.

Without pro-active replacement, if they are allowed to blow its top, conductive shrapnel is spewed shorting other critical components. There are high voltages (400 VDC) inside this DC-DC converter.

Our rebuild process includes replacement of all of these electrolytic capacitors and a bench simulated operational test including load testing.

BSM Module

Battery Safety Module (BSM)

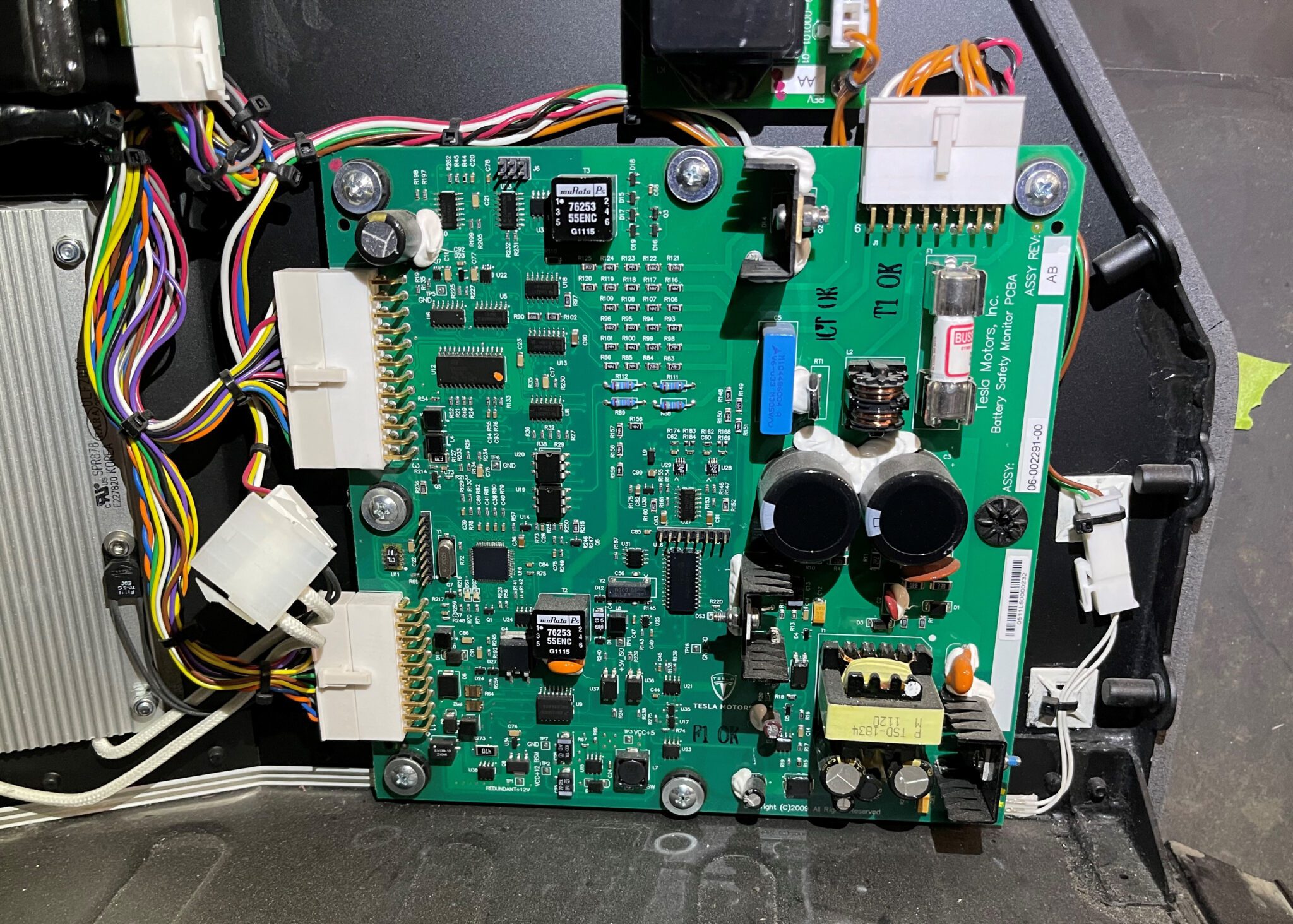

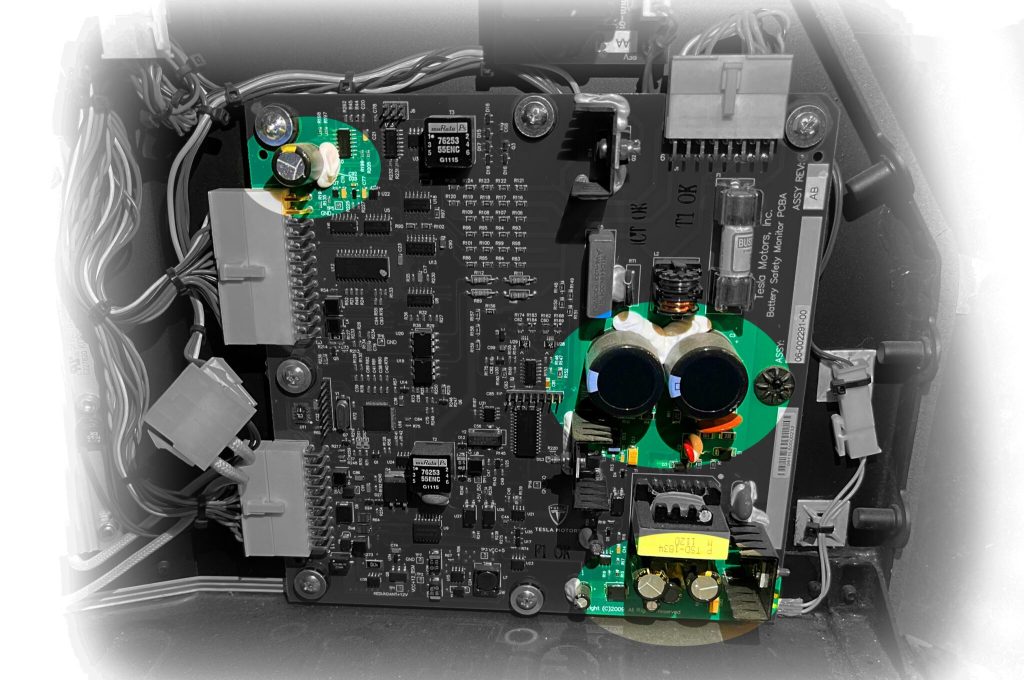

This Battery Safety Module (BSM) is fundamentally a logic board also buried deep inside the ESS Main Battery Pack.

Its function is to collect data about the health of the battery sheets and bricks, monitor vital safety functions such detecting water ingress, temperature, brick voltages, and is in constant communication with the PEM and VMS through a variety of safety interlocks.

It is located on the opposite side of the APS DC-DC Converter on the drivers side of the ESS main Battery Pack, containing aging components that need to be replaced every 8-10 years.

Rebuild - $395

This board also has a collection of electrolytic capacitors, and a relay, all wear items that are replaced during a rebuild.