Roadster Paint Codes

The finish on any car is under constant attack. Between road rash, rock chips, and parking lots, even the most well preserved car is going to end up with blemishes.

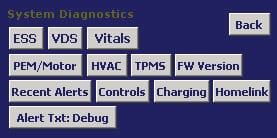

Diagnostic Screen Functions

This month we will dive into the unknown, the diagnostics menu reserved for the Service Center technicians. You may remember a previous newsletter were we gave the code to get into the hidden menu.

Roadster Valuation 2017

The number of Roadsters for sale seems to be increasing. With more cars available, cars sit longer waiting for buyers, and prices are declining. Supply is up, demand is down, and this may be why: The Lithium Ion cells in a ESS Battery Packs are End of Life (EOL). Let’s not forget Tesla originally projected […]

PEM Capacitor Failure

Our service partner in Europe received our first PEM failure due to capacitor aging. One capacitor, out of 19 in a PEM, had become resistive, and blew up inside the PEM sending shrapnel throughout the logic and circuitry. By a stroke of luck, the conductive debris did not short out anything.

A Brief Tesla Roadster History

This is a brief, but fascinating history of a car company that launched out of nowhere, and changed the transportation paradigm in just a few years.

Roadster Charge Specs & Tire Tech

Tesla Roadster Charge Table In an earlier Newsletter, we promoted 120 VAC charging vs 240/208 VAC charging. What you gain in reduced charging times with a 240 charge, may sacrifice long term reliability on key components in your car. (See the July Newsletter) This charge table is a guideline for various charge parameters. It is […]

Charging – 120 or 240 Volt?

Charging at 240 VAC, which feeds 40 Amps to the Roadster is definitely faster than using the 120 VAC 15 Amp charge cable. A full charge at 120 VAC could take 30+ hours, and conveniently stores in the car and plugs into a regular wall outlets.

Could this be the first Tesla Roadster?

Tesla Motors was created based on being inspired by an electric sports car, called the Tzero, developed by a small company called AC Propulsion Systems founded by Alan Cocconi in San Dimas, California in 1992.

What is inside your Roadster Battery Pack?

The main battery pack in the bowels of a Roadster is a 900+ lb monster, consisting of 6,831 Lithium Ion 18650 cells, mounted in 11 sheets.